Stone Countertops

- Igor Kondrasovas

- Jun 2, 2017

- 1 min read

Similar to what happens on the sheet metal fabrication, there is a huge waste in the natural stone countertops industry.

Every time a granite board will be cut (marble, onyx, travertine, granite, quartzite, etc), a layout optimization must take place to make sure you are getting more parts as possible.

Is is true there is an artistic concern to make the vein flow of the material, how the slabs will work together, etc.

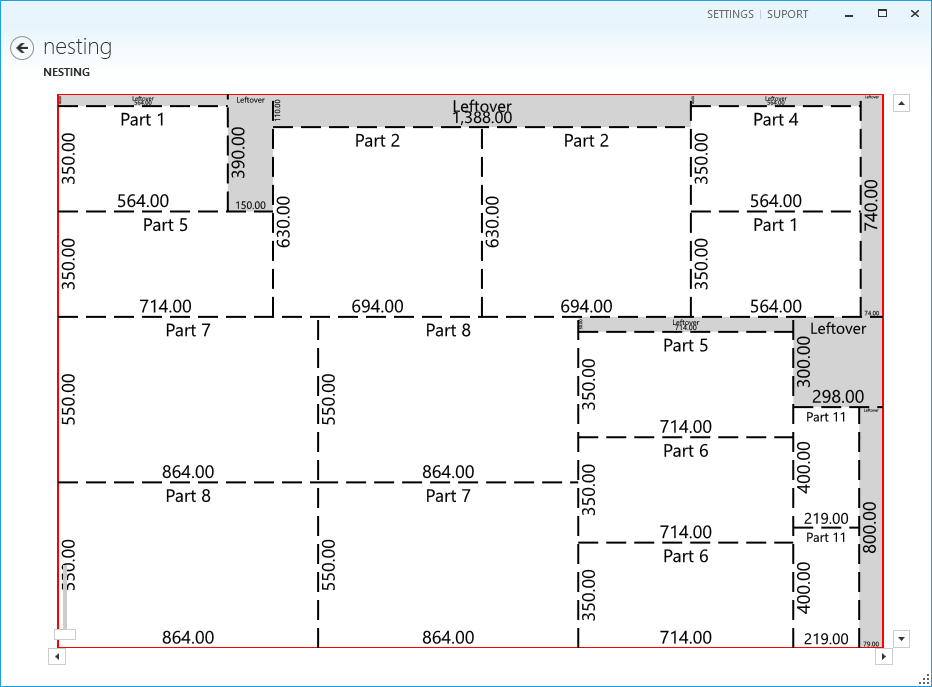

In addition, when the cutting layout is defined, there must be a cutting diagram available to the machine operator so there will be no guessing about what is the best cutting sequence.

Please have a look on the cutting diagram for the following image:

You can see this cutting patter is designed for cutting machines where each cut goes straight from one edge to the other of the board.

Comments